This Excel Sheet designs Base Plates for I-Shape Steel Columns. Edges must be properly secured and feathered with asphalt.

Steel Embed Plates Aka Concrete Embeds Steel Supply Lp

Use embed plates that are ½ 13mm thick.

. AISC Design Guide 1 - 2nd. Select steel grades and thicknesses for which preheat of the embeds will not be required. It is the responsibility.

If a wide-flange section is. Guidelines for Steel Plate Usage. Duane began by offering 10 tips to avoid pitfalls with welding on in-place embed plates as covered in Chapter 1414 of Design Guide 21.

Prime plate steel of any thickness or grade can be loaded into custom fabricated fixtures and studs are welded by hand or a state-of-the-art stud gun can be used. Steel embeds with Nelson studs welded. Despite the frequency of providing lateral stability to a steel frame in this way hitherto there has been no design guide available in the UK to suggest a common approach.

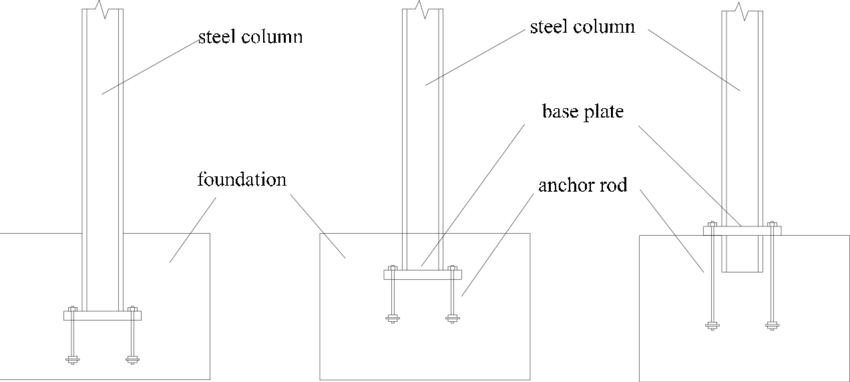

Studs Steel Embed Plate 4 Studs Order Quantity. The term base plate is commonly understood as referencing a steel plate placed beneath a column to distribute applied loads to a concrete member. Welding to in-place plates can cause cracking of the surrounding concrete due to expansion or distortion of the heated steel.

Ian Chin M. Minimum plate thickness is limited to 12 x anchor diameter. The plate is assumed to act as a cantilever beam fixed at the edges of the column defined by the geometry of a structural profile Figure 1.

Embed Plate Design. There is also a note on keeping the surrounding concrete from spalling when welding. 100 traceability is key and proper palletizing insures your embeds are getting to your job site every time.

Tomlinson This research project aims to improve the efficiency of the embedded plate design process since they are very common in buildings but often designed individually. PCI Design Handbook - Chapter 6 Connectio Design has a wealth of info and examples for the design of embedded plates in concrete using Deformed Bar Anchors and Headed Concrete Anchors. No Installations Work From Anywhere.

Design embed plate assemblies to resist distortion. Typical Base Plate Design. I am new to the use and design of embed plates.

Steel Embed Plate 4 Studs. Welding is used when more than one steel plate is used and they butt up to each other. Welded-headed studs have been used to connect con-.

The wood component of the beam The construction of the beam is also straightforward. The steel component of the flitch plate Beam assembly is typically comprised of A36 Grade ½ ¾ and 1 Thick Hot Rolled Steel in lengths up to 20 Long. It can be used for any profile or BUS as it is not linked to profiles tables.

Arrange anchorage elements away from the locations where field welds will be required. AG Base Plate with Moment Axial Compression. The façade or curtain wall elevator stairs operable partitions and other trades may request different tolerances.

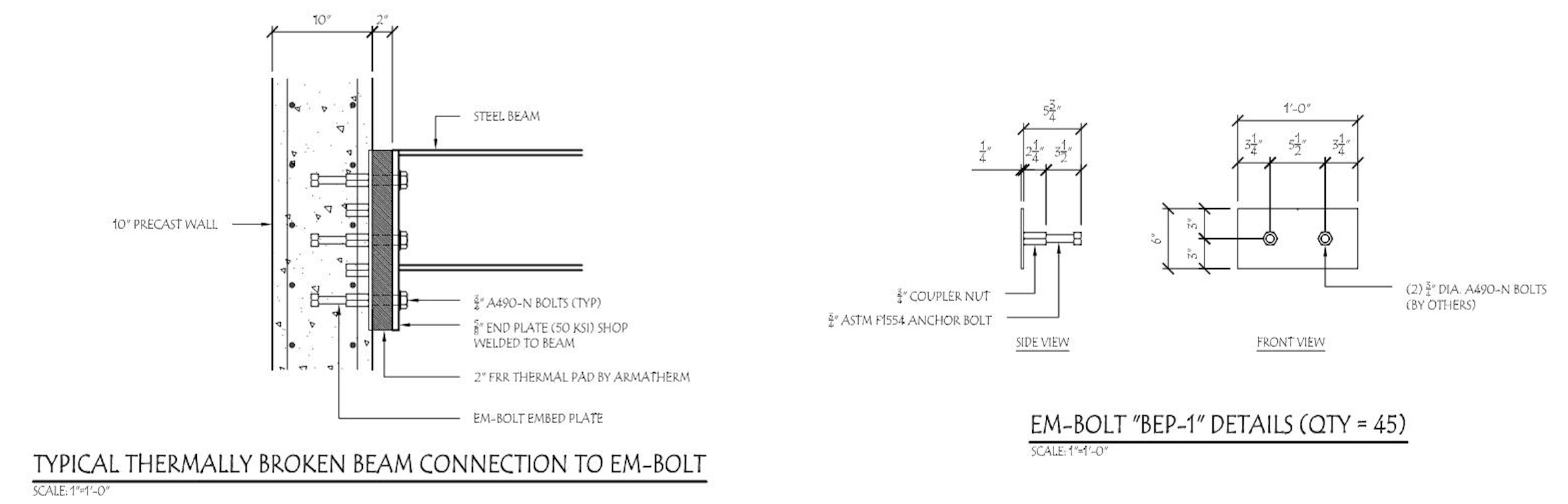

Research work that culminated in the design equations presented in Section 65 of the sixth edition of the PCI Design Handbook. 3445 19995. The use of steel plates cast into concrete elements to connect steel beams to is a common construction method where a steel frame surrounds a concrete core.

I n the precast concrete industry pre-cast components are typically con-nected by use of an embedded plate a majority of which are anchored with welded-headed studs. The behaviour of components in terms of resistance stiffness and deformation capacity is summed up for components in concrete and steel parts. Oengineer Structural OP 14 Jun 19 1452.

The focus of this research specifically is cast-in embedded plates with welded-on headed studs because of its prevalence in the industry and relatively easy. Of the aisc code of standard practice12 requires that embeds to receive structural steel be set to a tolerance consistent with those specified in section 713 for the erection of structural steel. Normally steel plates must extend at least one foot beyond the pavement opening onto firm ground.

The following tips can minimize the heat effects from welding. It covers both cases Large Small Eccentricity. Design Guide 2 Typical Design Steps Steel and Aluminum Structural Plate Design Guide Table of Contents This design guide is provided by Contech Engineered Solutions to assist designers with most applications and design aspects of MULTI-PLATE Aluminum Structural Plate ALSP Aluminum Box Culverts ALBC SUPER-SPAN.

Header studs stirrups concrete in compression concrete panel in shear steel reinforcement steel plate in bending threaded studs embedded plate in tension beam. With Bending Moment Axial Compression as per ASD. Select the correct size.

Made coated and cleaned correctly. Embed plates are a vital component in the construction industry and the best way to connect steel to concreteWelding studs are used to make the embeds fabri. Horizontal ones base plates.

Ad Integrated design standards including AISC ACI ASCE NDS and CSA. Ahle stocks common widths to match 2 X 8 2 X 10 and 2 X 12 lumber. Design and Analyse Your Model Online.

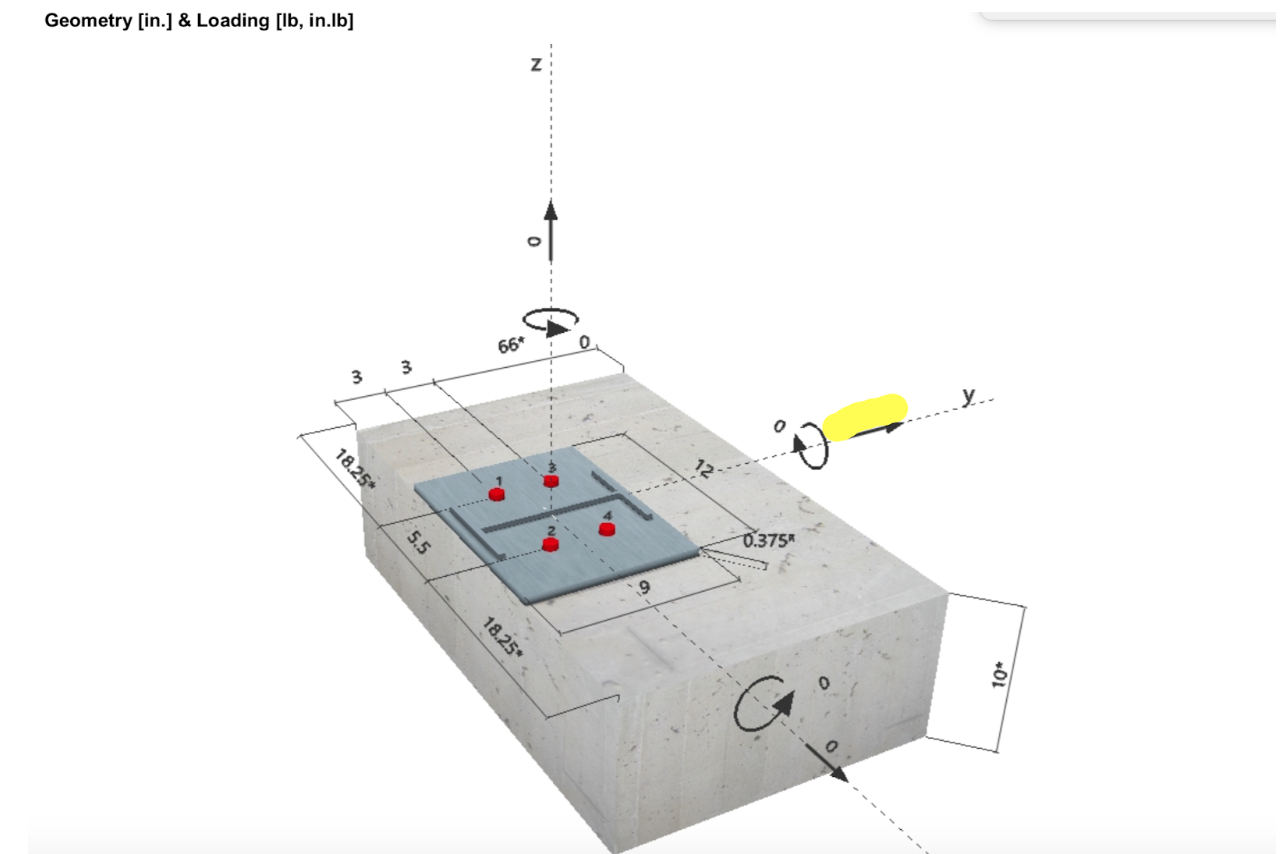

I was wondering if anyone is aware of any literature pertaining to Embed Plate design. I am working on designing some embed plates for steel beams attaching to ICF walls using Hilti PROFIS software.

Em Bolt Boltable Steel Embed Plate Installation For Structural Steel Foundations

Embed Plates With Concrete Thermal Break Technology Speeds Complex Building Construction

2 Embedded Column Bases Configurations Download Scientific Diagram

Concrete Column With Embed Plates Structural Engineering General Discussion Eng Tips

Em Bolt Boltable Steel Embed Plate Installation For Structural Steel Foundations

China Steel Embed Plates Custom Concrete Embeds From Metal Fabrication Factory China Embed Plates Concrete Embed

Em Bolt Embed Plate Design Using Hilti Profis Software Analysis

0 comments

Post a Comment